To access the basket, please sign in

Don't have an acccount? Register Now

/

Stressing is the process of adjusting the length of continuous welded rail (CWR) installed in the track so that the rail is neither in tension nor compression at a predetermined temperature. The temperature determined is a balance between the effects of low and high temperatures on the rails when installed in the track, and the track structure’s ability to resist buckling.

In the UK, the temperature that the CWR is considered to be stress-free is calculated as 27°C. This is called the Stress Free Temperature (SFT).

Before laying new track, repairing track, or changing the sleepers, the rail must be mechanically stretched or ‘stressed’ to ensure that the SFT of the rails falls within the required range. A hydraulic rail stressor, also known as a rail tensor or stressing kit, is used to accomplish this.

When choosing a rail stressor, you should consider factors such as capacity, ease of use, durability, reliability, and availability of support and maintenance services. However, ultimately safety should be the top priority when making such product decisions.

The Permaquip HSM70 Stressor is the most proven, safe and durable Stressor on the market with up to 78 tonnes of pull force.

Designed to be used in matching Permaquip OEM pairs to adjust the gap between rail ends for rail stressing, welding, repairing rail failures, and installing insulated joints. The non-slip clamps enable the gap to be maintained accurately in order to facilitate a stress-free weld.

Last year, the Permaquip ‘Captive’ design was further improved with class-leading ergonomics, approved by Network Rail. New handles are fitted to prevent slipping and provide dedicated hand positions for the cylinder and clamps, allowing for easier manual handling.

The Stressor can be broken down into a kit of parts for easier handling and transportation. Each component offers a two-person lift and can be handled with the new lifting / carrying tongs, for safer offset operation.

The Permaquip HSM70 Stressor is ideal for use in conjunction with the Permaquip Stressor Power Pack, available in both Petrol and Electric options.

The new Electric DC model utilises the same pump configuration as the Petrol Power Pack, with the added benefit of the zero-carbon emission engine. It can be handled using the new lifting / carrying tongs for reduced manual handling effort. With reduced HVAC and operating decibel levels and a constant operating (running) time exceeding 35 minutes.

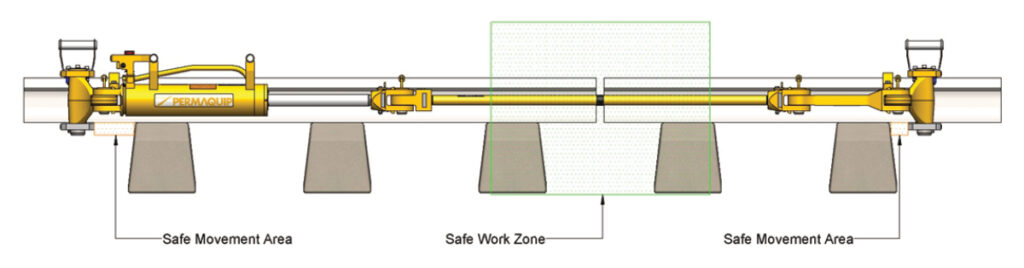

Captive rail stressing incorporates an anchoring system, which creates safe movement areas and a safe work zone. Resulting in the best all-round staff protection when in use. As well as, a more precise method of stressing, with greater control over the forces applied to the rail.

Free rail stressing involves stretching the rail without any anchoring system. Generally considered to be a less precise method of stressing, it can be more difficult to control the stressor and the rail.

In 2012, a review was conducted of the different designs of stressing kits available in the UK, prompted by the Infrastructure Group Safety Bulletin IGS 259. The review found that, between the two main designs, captive and free on rail, the captive design was considered the safest option for staff to use in all situations.

Regular servicing and maintenance are essential for keeping your Permaquip equipment functioning safely and effectively.

That’s why Permaquip sells specialised gauges and tools to help make servicing and maintenance easier. Our gauges are designed specifically to measure critical parameters, enabling service technicians to perform their tasks quickly and accurately and to diagnose and fix problems more effectively.

During the development of the NEW Permaquip HSM70 Stressor, new measurement parameters have been set in conjunction with the development of NEW Stressor Service gauges. Ensuring that Stressor servicing is consistent and straightforward.

The gauges include Fork & Clevis Hole Gauge, Link Plate Gauge, Pins Gauge, and Fork & Clevis Gauge.

The tools include C Spanner (for the replacement of Stressor Ram Seals), Pressure Relief Tools (Flat Faced), and Pressure Relief Tools (Screw Type).

For instructions on how to use the gauges, refer to the latest edition of the Permaquip Stressor Service Guide Issue 5 (MAN-M-O-110-05).

Furthermore, familiarisation training is also available for our gauges and tools, helping to ensure that they are used correctly and technicians can get the most out of them.